Check Out This Wrap Up Video Of The #NationalCandyMonth Event We Held In Partnership With FamousDC.

#NationalCandyMonth Featured Member Company: Adams & Brooks, Inc.

johnadamVideoScreenShot

We Partnered With The U.S. Chamber Of Commerce Global Intellectual Property Center And The Senate Press Secretaries Association On An Event Highlighting #NationalCandyMonth.

Read This Op Ed By Mitchell Goetze: Candy Industry Continues To Sweeten Baltimore

We Celebrated #NationalCandyMonth By Sharing Sweet Treats & Industry Information At Metro Center Station.

#NationalCandyMonth Featured Member Company: Galerie

galerieVideoScreenShot

#NationalCandyMonth Featured Member Company: Just Born Confections

JustBornVideoScreenShot

Check Out FamousDC’s Recap Of Our #NationalCandyMonth Reception Held On Capitol Hill.

#NationalCandyMonth Featured Member Company: Project 7

project7VideoScreenShot

Congressional Candy Caucus Co Chair Annie Kuster (D NH) Visited Our Office During #NationalCandyMonth.

Bon Bon Jovi #NationalCandyMonth #NCACelebSweets

Congressional Baseball Game: Fans And Players Got To Celebrate #NationalCandyMonth By Enjoying Sweet Treats After The Congressional Baseball Game.

We Teamed Up With Ferrero USA For A Candy Car Caravan Around Washington, D.C. During #NationalCandyMonth.

We Partnered With FamousDC To Hold A #NationalCandyMonth Reception On Capitol Hill.

We Celebrated #NationalCandyMonth By Sharing Sweet Treats & Industry Information At Capitol Hill Metro Stations.

#NationalCandyMonth Featured Member Company: Jelly Belly Candy Company

jellybellyVideoScreenShot

We Delivered #RandomActsOfSweetness To Brielle Colby At Javelin.

brielle

We Celebrated #NationalCandyMonth And Airheads 30th Anniversary By Sharing Treats & Information About The Industry At Capitol South Metro Station.

Britney SpearsMint #NationalCandyMonth #NCACelebSweets

#NationalCandyMonth Featured Member Company: Enstrom Company

enstromVideoScreenShot

We Placed Big League Chew In The Dugouts At The Congressional Women’s Softball Game.

cwsoftball

#NationalCandyMonth Featured Member Company: Spangler Candy Company

Spangler_Video_thumb

GIFOGRAPHIC — Fun Facts About The Companies That Make Chocolate, Candy, Gum And Mints.

U.S. Representatives Walorski, Kuster Launch Congressional Candy Caucus In Conjunction With #NationalCandyMonth

patrioticcandy

We Celebrated #NationalCandyMonth By Sharing Sweet Treats & Industry Information At Capitol South Metro Station.

IMG_3475

Michael Jordan Almond #NationalCandyMonth #NCACelebSweets

We Delivered #RandomActsOfSweetness To Cathy Merrill Williams, Rebecca McFarland, Susan Farkas At Washingtonian.

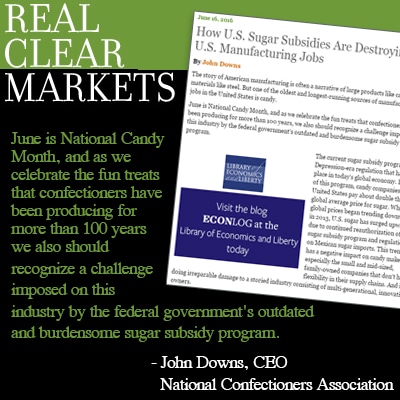

Real Clear Markets: NCA CEO John Downs Says Sugar Subsidies Are Destroying U.S. Manufacturing Jobs

We Delivered #RandomActsOfSweetness To Megan Wilson At The Hill.

Politico Influence Covered NCA’s Mike And Ike Candy Sampling Event At Farragut Square.

PoliticoInfluence

Liz Dee, Smarties Candy Company, Visits Congressman Leonard Lance (R NJ) To Promote National Candy Month And Jobs In Manufacturing On Capitol Hill.

Two Members Of Congress Announce A New Bi Partisan Candy Caucus.

PoliticoPro_Caucus_Thumb

Candy Is A Special Treat That Plays An Important Role In Cultural Traditions, Seasonal Celebrations And Family Occasions Here In The U.S. And Around The World.

ThatPower

#NationalCandyMonth Featured Member Company: Smarties Candy Company

Dee_Video_Thumb

#NationalCandyMonth Featured Member Company: The Blommer Chocolate Company

Blommer_Video_thumb

Lucille GumBall #NationalCandyMonth #NCACelebSweets

465,000 Jobs Rely In Part On The Manufacturing Of Confectionery For Their Livelihood.

ncmInfographic_thumb

NCA Chats With The Hill About Trends In Chocolate, Candy, Gum And Mints For #NationalCandyMonth.

We Sent #RandomActsOfSweetness To Bryce Harper Of The Washington Nationals.

#NationalCandyMonth Featured Member Company: Jenco Brothers’ Candy

Jenco_Video_thumb

We Delivered #RandomActsOfSweetness To Melissa Foxman At The Entertainment Software Association.

Check Out This #NationalCandyMonth Op Ed By NCA President & CEO John Downs In Retail Leader.

RetailLeader

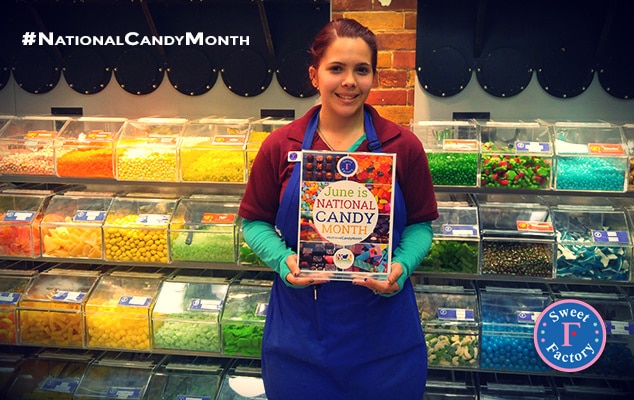

A Sweet Factory Associate Displays Custom In Store Signage Created By NCA To Help The Candy Retailer Celebrate #NationalCandyMonth.

SweetFactory_update

#NationalCandyMonth Featured Member Company: Atkinson Candy Company

Atkinson_Video_thumb

HariBo Jackson #NationalCandyMonth #NCACelebSweets

Check Out Our #NationalCandyMonth Interview With FamousDC.

famousdc

We Delivered Our First #RandomActsOfSweetness To Benny Johnson At Independent Journal.

randomact_1

Check Out Our Interview With WJLA On The First Day Of #NationalCandyMonth.

We Kicked Off #NationalCandyMonth By Sharing Sweet Treats & Industry Information At Capitol Hill Metro Stations.

Read The #NationalCandyMonth News Release.

Check Out This #NationalCandyMonth Video By Artist Howard Lee.

video_thumb